We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Tunze's Quest for the Prefect Auto-Top-Off, Meet the Gen 3 Osmolator

Tunze was founded in 1960 by Norbert Tunze, and their first product was the aquarium powerhead, followed by the first venturi driven protein skimmer in 1963, until that point aquariums ran only on air pumps. And can you believe that there were no motorized flow devices? Over the years Tunze has pioneered many new and innovative products, in 1985 they introduced the first ever ATO system, the Osmolator, a contraction of Osmotic Regulator. This article is about the Tunze Osmolator and its impact on the aquarium hobby. We hope our newer aquarists and old dogs like me can appreciate the passion & determination in creating a business that has been apart of our hobby for so many years.

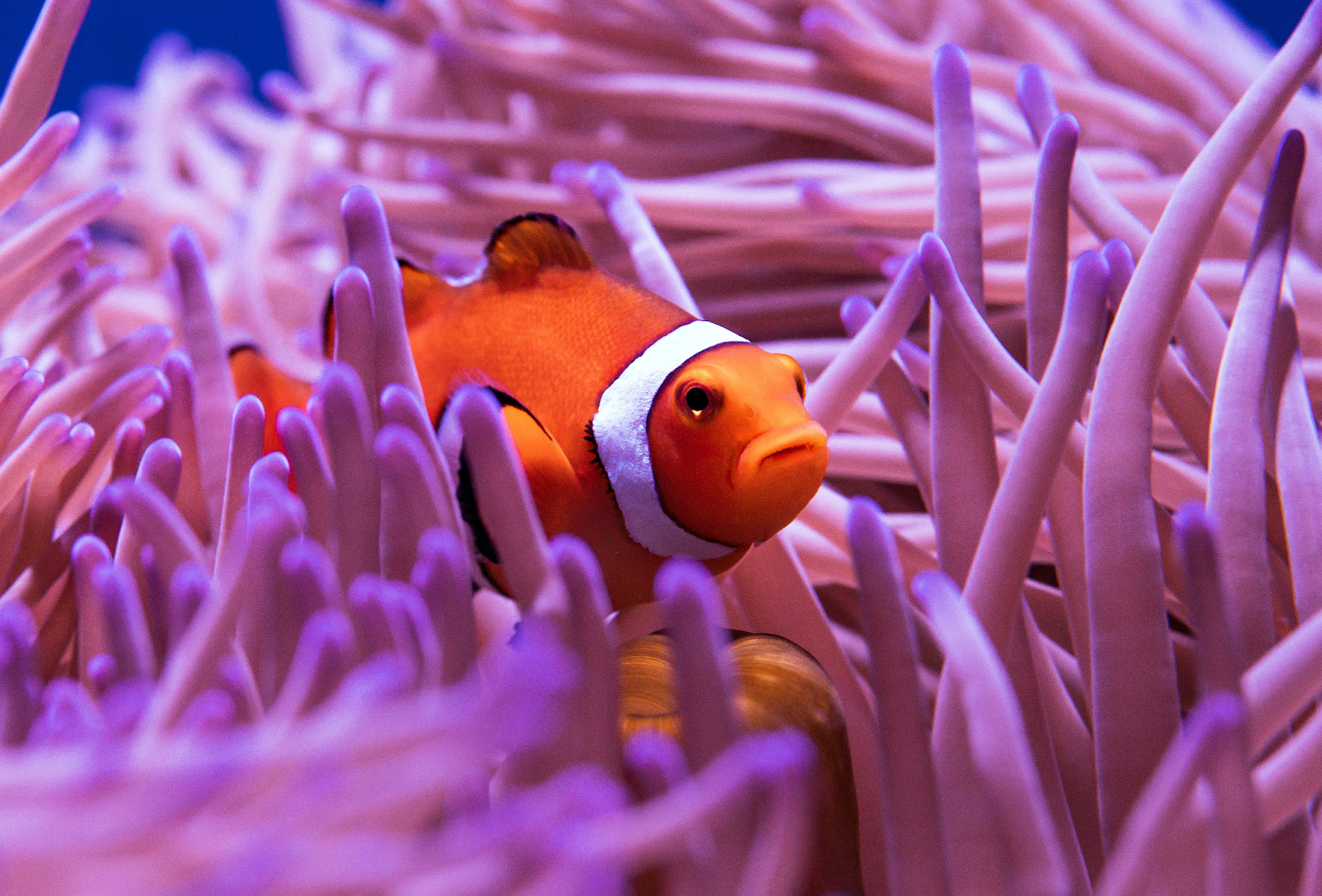

Despite how ubiquitous using an Aquarium Auto Top-Off is now, at the time this product was largely derided as an innovation for only the laziest of hobbyists. However, Norbert had been an aquarist for much of his life and the development stemmed from a personal interest in being able to raise Lysmata sp. shrimps. On numerous occasions he had eggs, even hatches, advanced through a couple larval phases but they never made it to maturity. Convinced from measurements with his earlier invention of the first aquarium conductivity monitor, the issue was Osmotic stability affecting the larvae at critical molting stage. As such, Norbert set out to invent a system that would make this regulation possible.

This first Osmolator or Osmolator 3150 used 2 float switches one was a redundancy for safety, a 10 minute time limit was an additional safety against flooding in the event both floats failed. The earliest version used a peristaltic pump before Tunze transitioned to the jet style metering pump that was used all the way through to the next generation Osmolator 3155. Using this metering pump reduced costs considerably and allowed a faster fill rate.

In 2000 the Osmolator was redesigned with true redundancy built in. The new safety features required two independent technologies, now under the direction of his son Axel Tunze. The new Osmolator featured the 1st ever optic sensor which was added and produced in house. This optical sensor became the primary sensor with a backup float that included an independent override circuit for built in redundency and peace of mind. The 10 minute safety timer was retained and a 4 light display with far more feedback was added. This system became what is most likely the best selling auto top-off of all time, while it had 3 notable upgrades over the years, the basic system remained unchanged.

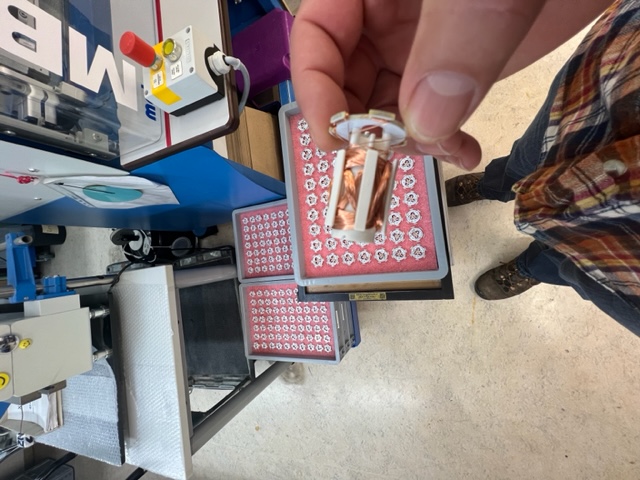

Fast Forward to 2018, Tunze began work on a next generation Osmolator now called the Osmolator 3 (3154.000) Auto Top Off. The primary goals of the development were fewer wires, a more compact appearance and more modern look. This older style pump for Tunze, as well as competitors, was generally considered the achilles heal of most ATO’s. Tunze started the process of Developing the Osmolator around the pump, which was no easy task! The Osmolator Pump needed to be reasonably priced, able to be produced in-house at the Tunze factory in Penzberg Germany. It also needed to produced in massive quantities and exceed every competing pump in silence, reliability and durability. After many years of trial and error and a lot of prototypes and tests, Tunze finally had the pump ready for production!

In parallel Tunze worked on the controller, there were many ideas tried for the backup sensor. Floats are bulky and would not lend themselves to the compact design they desired so the goal was to get away from the float switch method. After further design and testing Tunze created a unique system they developed which includes the use of a micro heater paired with a micro temperature sensor and a thermal backup switch.

After further testing, the Osmolator ATO 3 entered production in October 2023. Functionally it is very similar to the last generation, optic sensor as the primary sensor but with a thermal switch that replaced the float as a backup. The 10 minute time limit was retained as in the original design. Now instead of 4 lights, a single RGB array gives 9 unique color patterns for diagnostics and the true DC pump motor has a two way data connection to the controller and pump issues are displayed as an orange light error code.

The old system of a control box with 4 wires (pump, power, float, optic sensor) is now a magnet holder with sensors and controller built in and a single Y-cable the branches off into a water proof pump connection. While it may be open and look unsealed, the power connection is actually a very high quality Japanese produced connector that has gold plating and extremely high corrosion resistance. Likewise the power supply was updated to a medical grade power supply with much more advanced safety against any shorts or electrical hazard. The pump connection can be extended with up to 2 x 3 meter extensions giving a maximum length of a bit over 20ft from the pump to the controller. The Osmolator 3 pump is capable of 20ft of head pressure when set to boost mode. By default the pump is set to 12ft of head pressure and runs at a quieter, lower speed setting becuase most ATO applications do not exceed 12 feet of head pressue. This system works equally well in freshwater or saltwater and unlike any of our competitors, it is actually produced by Tunze in Germany.